MM AQUA TECHNOLOGIES LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MM AQUA TECHNOLOGIES LTD.

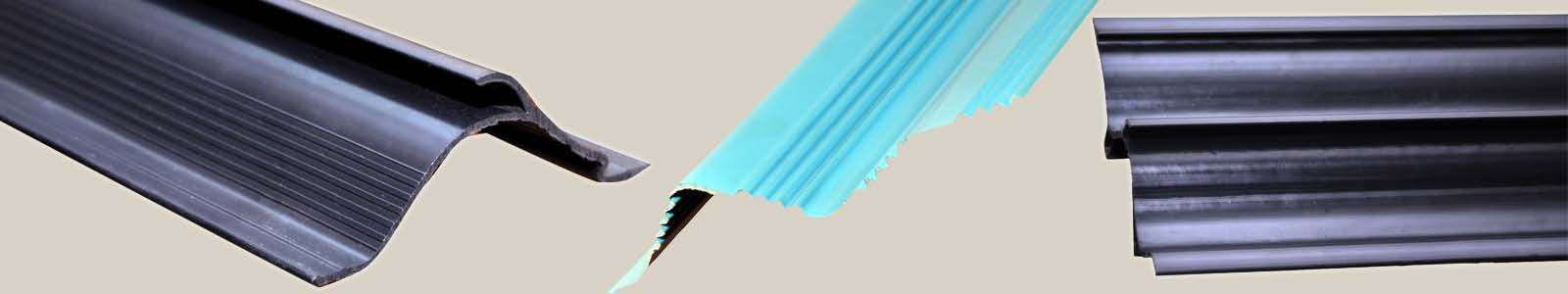

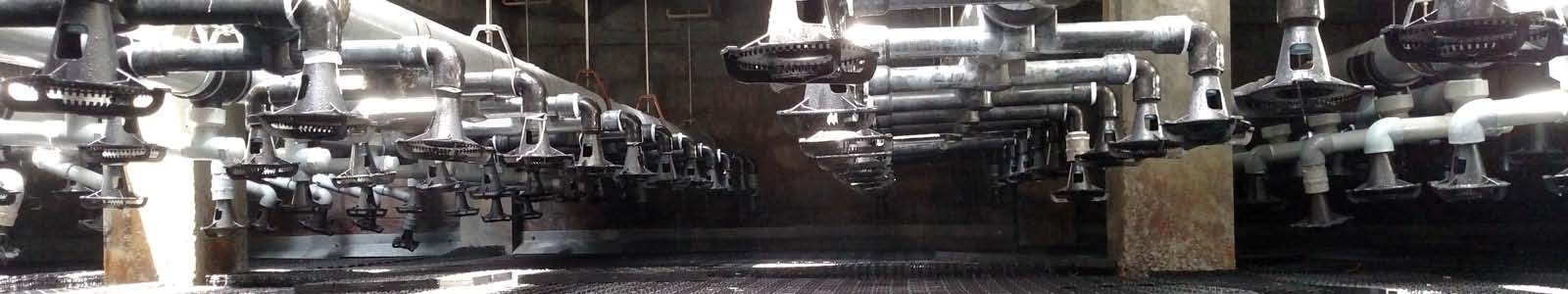

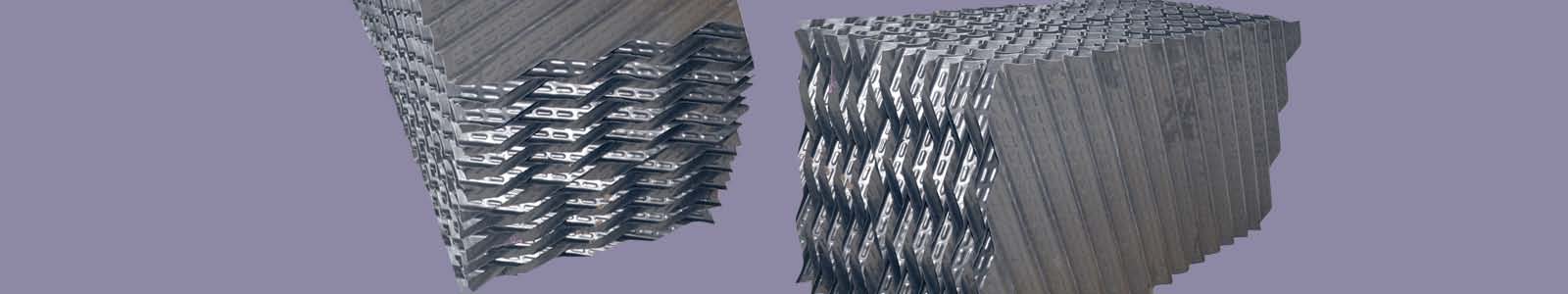

Film Fill

MM Aqua is into manufacture and marketing of various types of fill design suitable for different water quality. These fill Media are manufactured meeting CTI standards.

Fill Media manufacturted is of international quality and are prefered by leading consultants like NTPC, Fitchner, M N Dastur, Desein, TCE, EIL and NPC etc and is used by all leading Cooling Towers manufacturers.

Fill media manufacture by MM Aqua is exported to countries like Malaysia, Singapore, Thailand, Middle East, Canada, Australia, South Africa, Brazil, UK etc.

MM Aqua has big production capacity to meet large order Qty in required project schedule.

MM Aqua offers following type of fill media.

Film Fill : – C10.12 / C10.19 / C10.27

Advantage of MM Aqua film fill.

Continuous Forming : Continuous forming process allows free flow of material during the stage of formation. Additional requirement of raw material is met hence no thinning takes place at crests & troughs.

Double Edge Folding : MM Aqua’s manufacturing technique has the ability to fold the edges of the sheets providing stronger edges, which gives extra protection against water loads and shear force form beams. It also protects the fill from damages during installation & maintenance.

Uniform Thickness : Provides uniform strength in fill sheets all along the fill surface.

Micro structure : Unique shape and dimension provides long retention time and thus longer time for heat transfer.

Longer Length : Allows the structural designer to reduce number of support beam thus inturn reduces the pressure drop and cost of construction.

In Conventional vacuum forming the sheets being formed needs anchoring both ends of the sheet, which results in stretching of material. Weak spots of lower tickness at crest and trough and at times also on flute surface are formed. Vacuum-formed sheets suffer from unpredictable thikness due to material stretching during the process. reduction in thickness is to the tune of 40%. However, by leaving one end free during continuous roll forming, MM Aqua avoids the undesirable results.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.